The upfront investment for private and municipal actors in a new Waste to Energy facility is largely

location-dependent. Some national governments, particularly the Peoples’ Republic of China and

some countries in the European Union, heavily subsidize investments in new WtE facilities. In the

case of China, government subsidies reduce the per annual ton price tag by over a third. The United

States does not subsidize new WtE facilities in this manner. In the US, public-private partnerships are

a common arrangement for the financing of WtE projects. In many cases, the municipality will

provide some seed capital and assurances to lenders for future payments. The private entity will also

generally provide some seed money, but will be fully responsible for facility operations with limited

oversight provided by the local government.

Initial Facility Construction

In general, initial WtE facility construction costs can be roughly approximated using the following

equation:

I = 2.3507 x C 0.7753

Where:

I = Investment cost in millions of USD

C = Plant capacity in 1000 metric tonnes per year.

(Equation adapted from “Techno-economic assessment of municipal solid waste incineration plant”,

Haghi, 2015)

This equation expresses the average international facility investment cost. This estimate may vary

widely depending on regulatory requirements and labor and supply logistics, and the availability and

buildability of a site deemed suitable. Using this equation to calculate a rough estimate, a new

facility with a capacity of 600,000 tons of waste annually would cost approximately $310 million.

Facility Operations and Maintenance

WtE facility operations and maintenance costs can be roughly approximated using the following

equation:

A = 0.0744 x C 0.8594

Where:

A = Operations cost in millions of USD

C = Plant Capacity in 1000 metric tonnes per year.

(Equation adapted from “Techno-economic assessment of municipal solid waste incineration plant”,

Haghi, 2015)

This equation approximates an average for international facility operations cost per year. The

estimated average facility operations cost is affected by many factors including labor, equipment,

administrative, and maintenance costs, to name a few. Operations and maintenance costs may also

change significantly depending on local, regional, or national regulations, particularly those

impacting emissions regulations. In the United States, as air quality standards evolve, WtE facilities

have had to be retrofitted to adapt to increasingly-strict air quality regulations. These upgrades

sometimes cost as much as hundreds of millions of dollars.

Facility Tipping Fees and Other Sources of Income

Given the costs discussed above, in order for a WtE facility to break even it typically charges on the

order of $35 to $60 per ton in tipping fees if its bonds or loans are paid off (i.e., prior to financing

charges). If the bonds/loans are not paid off, the tipping fees may be upwards of $100 per ton. For

reference, the average landfill tipping fee nationwide in 2017 was $51.82. The broad range of

tipping fees for WtE are largely a result of the varying up-front cost of construction and the range of

facility operations.

However, there are other sources of revenue available. The facility can provide dependable electrical

energy for thousands of households. For example, the City of Spokane’s Waste to Energy Facility

processes up to 800 tons of waste per day (over 290,000 tons per year) and makes $5 million per

year in electricity sales from combusting that waste. It is important to note that electricity rates vary

significantly from region to region.

The recyclable metals left at the end of the process can be sold to manufacturers. Recyclable metals

sales are dependent on local or regional demand and the quality of the metals. The supply of

recyclable metals of a certain quality or type fluctuates as the incoming waste composition may

change over time, and all metal unit value is heavily impacted by fluctuating, sometime volatile,

open-market commodities pricing.

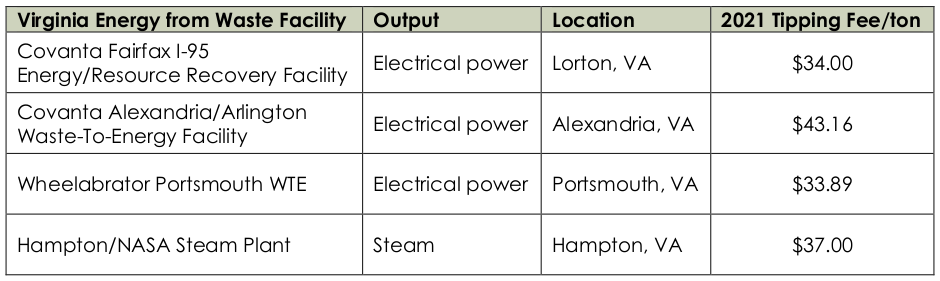

SCS surveyed the tipping fees for the four EFW facilities in Virginia as of CY 2021. Results of the

survey are presented in Exhibit 3 below. Note that the Hampton/NASA facility is typically referred to

as a steam plant rather than a traditional WtE facility.

Inventory of 2021 Virginia EFW Facility Tipping Fees